- AMD Community

- Blogs

- Corporate

- Ultrathin SOLIDWORKS Workstations - Benchmarking t...

Ultrathin SOLIDWORKS Workstations - Benchmarking the Lenovo ThinkPad P16s AMD

- Subscribe to RSS Feed

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

All performance claims in this blog are based on 3rd party testing from GoEngineer.

Back in May 2022, GoEngineer had the opportunity to benchmark Lenovo’s second-generation P14s laptop. This machine did something we had never before seen in an ultraportable, lightweight, and cost-effective design: it ran SOLIDWORKS well. With its AMD Ryzen 7 PRO 5850U processor and onboard graphics, it performed well on smaller level assemblies (provided you made some easy tweaks to SOLIDWORKS settings). But now, with Lenovo’s latest release of the ThinkPad P16s and ThinkPad P14s Gen 3, ultrathin SOLIDWORKS performance has gotten even better; no tweaks necessary.

AMD BACK IN THE RING FOR ROUND 3

The heart of the Lenovo P16s and P14s AMD laptops is the AMD Ryzen 7 PRO 6850U processor. Like the Ryzen 7 PRO 5850U from last year, this processor serves as both CPU and GPU, eliminating the chassis space, battery consumption, weight, and cost that a discrete graphics card demands. The 6850U is the latest and greatest in AMD’s high-efficiency mobile processor lineup, featuring eight cores and 16 threads of CPU and 12 cores of RDNA 2 graphics, all in a 15-28W package.

As for full laptop configurations, both the P14s Gen 3 and P16s also offer a slightly cut-down, six-core Ryzen 5 PRO 6650U processor, though we strongly recommend the Ryzen 7 PRO tested here. Both machines also offer touch and non-touch screens, with 1080p and higher resolution options. Customers can choose between 16GB and 32GB of DDR5 memory. We recommend 32GB for this system since integrated GPUs (unlike their discrete counterparts) share system memory. Storage options range from 256GB to 2TB PCIe Gen 4 SSDs, and battery options are 52.5Wh with fast charging and 86Wh without fast charging.

We tested a P16s outfitted with 32 GB of RAM, 1 TB PCIe SSD storage (goes up to 2 TB), and a 16” 2560 x 1600 anti- glare IPS display panel. This configuration came in comfortably under $2,000.

Our first impression of the P16s was that it felt even lighter than the P14s Gen 2, and the fiberglass-reinforced plastic with magnesium frame gave it the feel of a quality product. Owing to the 16” footprint, the keyboard has a full numpad, saving us from entering our numbers from the top row of the keyboard. It’s the little things.

OUR SOLIDWORKS TESTING

For those of you who are unfamiliar with GoEngineer, we put great effort into SOLIDWORKS benchmarking, and we regularly give talks on the topic at SOLIDWORKS/3DEXPERIENCE World and throughout the year in our webinars. We have been testing hardware for SOLIDWORKS performance for ten years and have developed a custom-built test suite to run standardized, common operations on a variety of real-world representative models. Our data captures true SOLIDWORKS capability far beyond what the built-in SOLIDWORKS benchmarks can do.

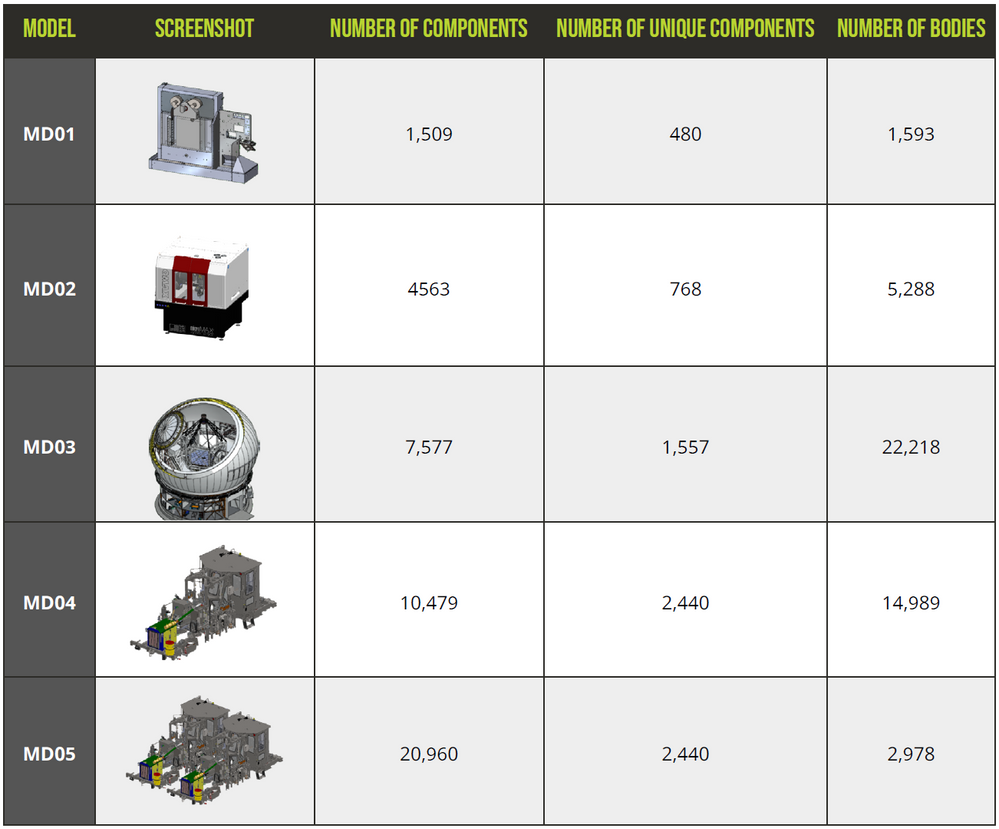

Our GoEngineer Standard Benchmark is a battery of tests we can run on several SOLIDWORKS models representing different levels of assembly complexity:

Figure 1. Our SOLIDWORKS benchmark models and their sizes.

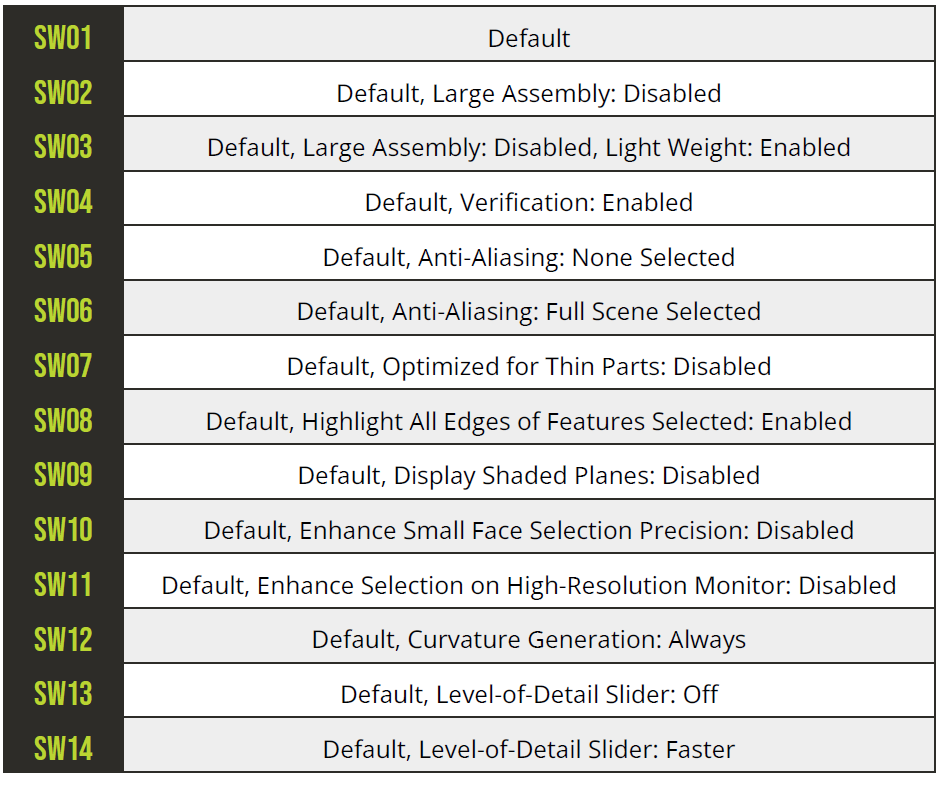

The test operations include opening and saving assemblies, Pack and Go, assembly and part creation, and many other daily operations SOLIDWORKS users perform. This test is typically dependent on the CPU’s single-thread performance. SOLIDWORKS settings can greatly impact the results, so, when we conduct the full battery of tests, we run the GoEngineer Standard Benchmark in 14 settings configurations:

Figure 2. The GoEngineer SOLIDWORKS Standard Benchmark tests these configurations.

The results of this test are measured in minutes to complete the sequence of operations, meaning lower is better. You can think of it as a relative measure of how much “waiting on SOLIDWORKS” you’ll be doing as you try to get your job done.

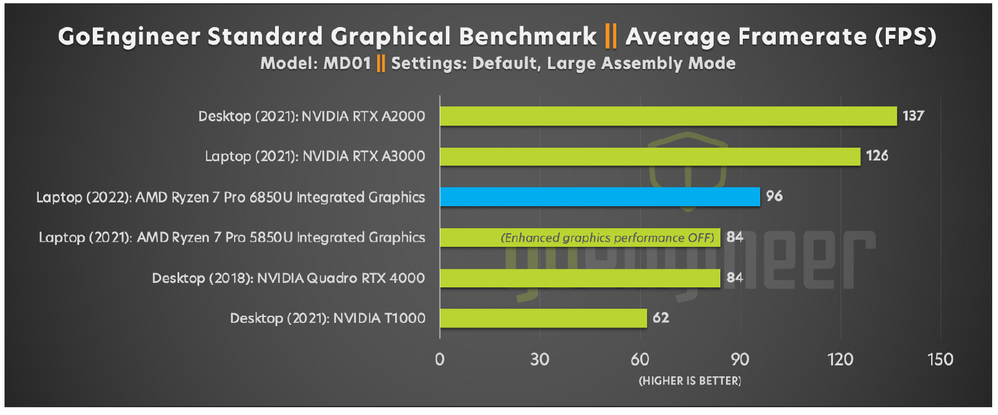

To evaluate 3D viewport graphics performance, we have our GoEngineer Standard Graphical Benchmark, which automates on-screen model manipulation and records frames per second. This is a measure of the graphics card’s capability to deliver smooth visual output as you manipulate your 3D model. Using propriety techniques, we perform a series of pans, rotates, and zooms on our benchmark models, recording SOLIDWORKS display refreshes over the test duration.

The results of this test are measured in average frames per second. In this case, higher is better (it will look smoother and feel snappier) – but only up to a point. This is because a computer monitor is limited in how many frames per second it can display. This limit is called the monitor’s refresh rate, measured in hertz. If the GPU delivers frames faster than the monitor can refresh the display, the excess frames will be discarded.

For example, if your GPU delivers 200 FPS to a 60 Hz monitor, you will only actually see 60 FPS. Therefore, when interpreting graphical benchmark results, keep in mind that your monitor’s refresh rate (the industry standard is 60 Hz), is the highest performance you can experience.

“High refresh” monitors are becoming more common (they can feel quite a bit more responsive), but you may have to compromise on price, panel size, resolution, or color gamut. It is also important to note that the graphical benchmark results are an average, so it makes sense to seek a little headroom for FPS dips.

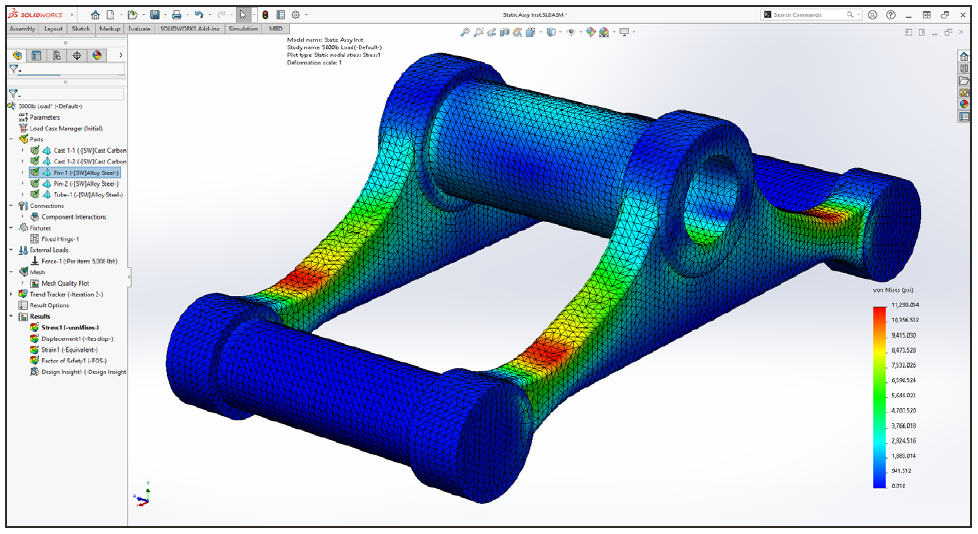

For our SOLIDWORKS Simulation benchmark, we apply a 5000 lbf linear static load on a 2,000,000-node model with 6,000,000 degrees of freedom. Results are measured in minutes to complete the analysis. The faster the analysis, the sooner you can get back to work.

Figure 3. Our SOLIDWORKS Simulation benchmark model.

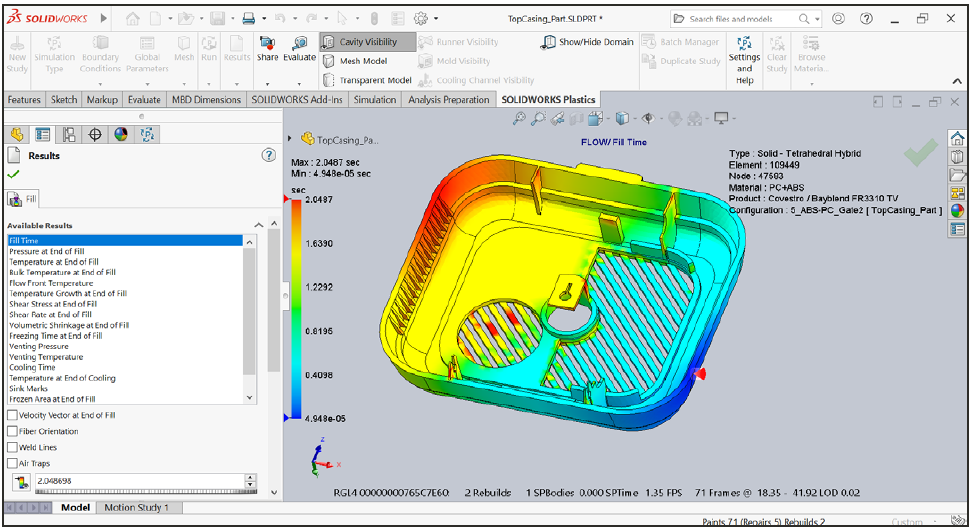

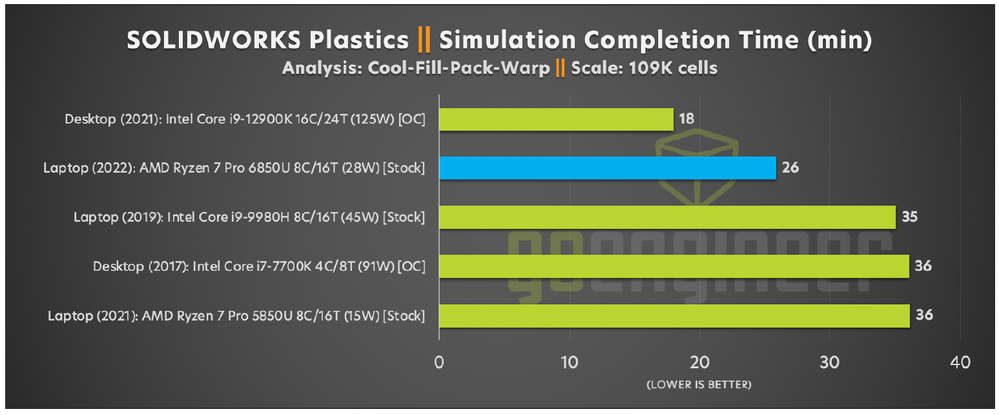

For our SOLIDWORKS Plastics benchmark, we run the fill-cool-warp cycle on a smoke detector’s plastic casing, an official SOLIDWORKS demo model. Results are measured in minutes to complete the analysis. The faster the analysis, the sooner you can get back to work.

Figure 4. Our SOLIDWORKS Plastics benchmark model.

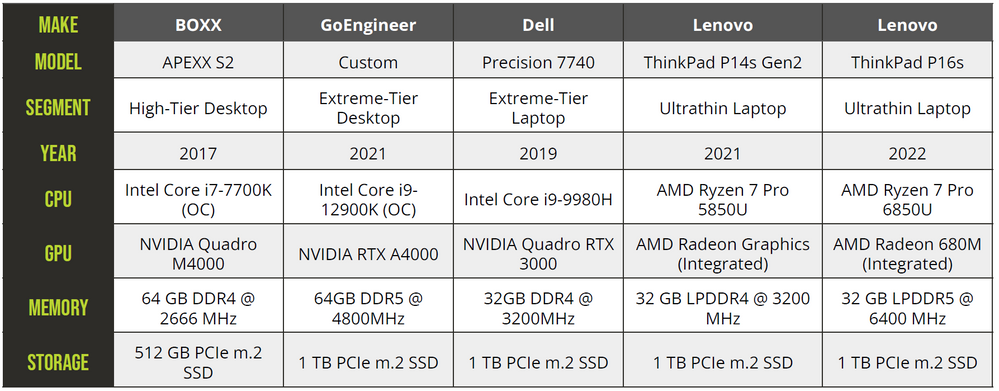

In testing the Lenovo ThinkPad P16s for CPU performance (i.e. Standard Benchmark, Simulation, and Plastics tests), we’ve compared it to the P14s Gen 2 and a range of desktop and laptop systems that represent the kinds of workstations a current SOLIDWORKS user might be familiar with:

Figure 5. Machines included in this SOLIDWORKS CPU performance test battery.

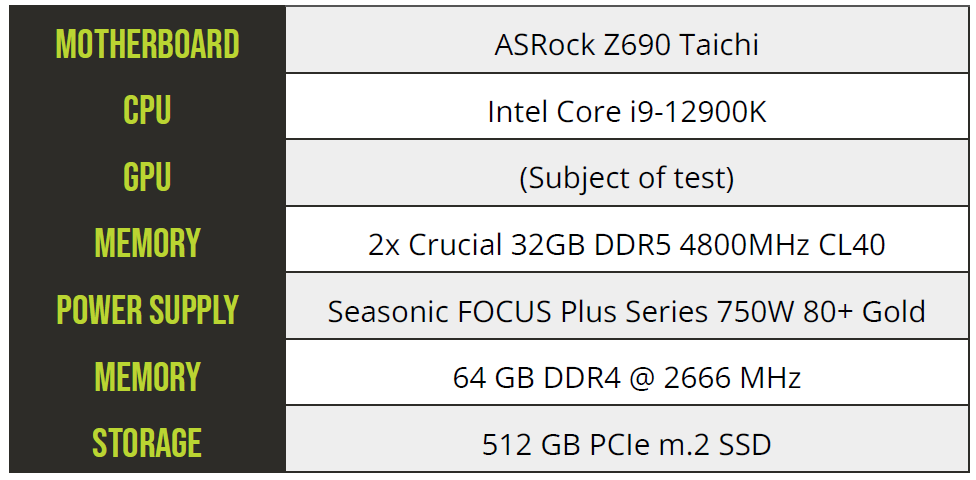

For our GPU performance benchmark (i.e. Standard Graphical Benchmark), all desktop GPUs are tested on our test bench:

Figure 6. Our test bench for SOLIDWORKS GPU performance testing.

Laptop GPUs are nonremovable and remain in their original system.

For the GoEngineer Standard and Standard Graphical Benchmarks, we focused on model MD01, which has 480 unique and 1509 total components, as we felt this best model matched the intended use case of this machine. We left SOLIDWORKS settings at default, with Large Assembly Mode automatically toggling on, as the test model exceeds 500 components.

PERFORMANCE: SOLIDWORKS 3D CAD

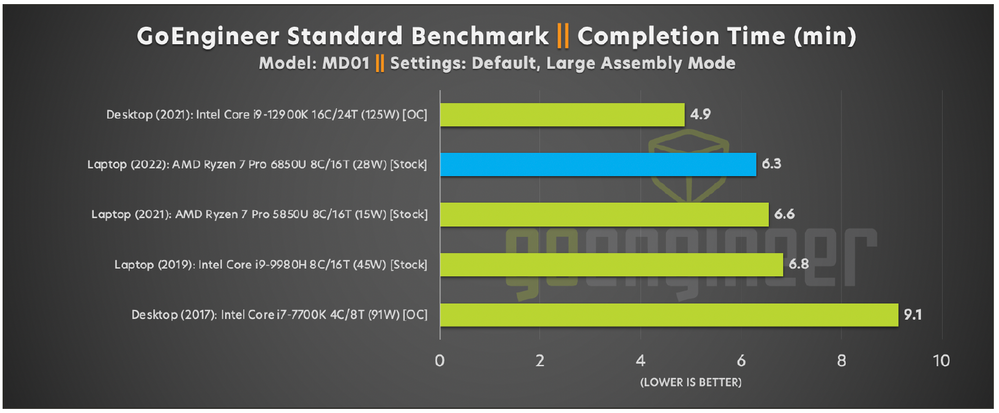

Figure 7. GoEngineer SOLIDWORKS Standard Benchmark results.

For the GoEngineer Standard Benchmark, this laptop is comfortably situated amongst the other SOLIDWORKS workstations. It should provide a familiar quality CAD experience. Performance in this test is dependent primarily on the CPU, and the Ryzen 7 PRO 6850U can consistently run at or near its 4.6 GHz maximum boost speed. This test shows

a 5% generational improvement from the 5850U to the 6850U, but things get more dramatic from here.

PERFORMANCE: SOLIDWORKS 3D CAD GRAPHICS

In our testing of the previous generation P14s, we had to tweak a setting to get the expected level of performance.

To reach that 84 FPS, we set “Enhanced graphics performance OFF”. With the P16’s Ryzen 7 PRO 6850U, we have an

unambiguous and significant improvement: 96 FPS without changing our standard “Enhanced graphics performance

ON” setting. This fix also makes the machine a more viable SOLIDWORKS workstation, as “Enhanced graphics performance

ON” allows users to work with even larger assemblies.

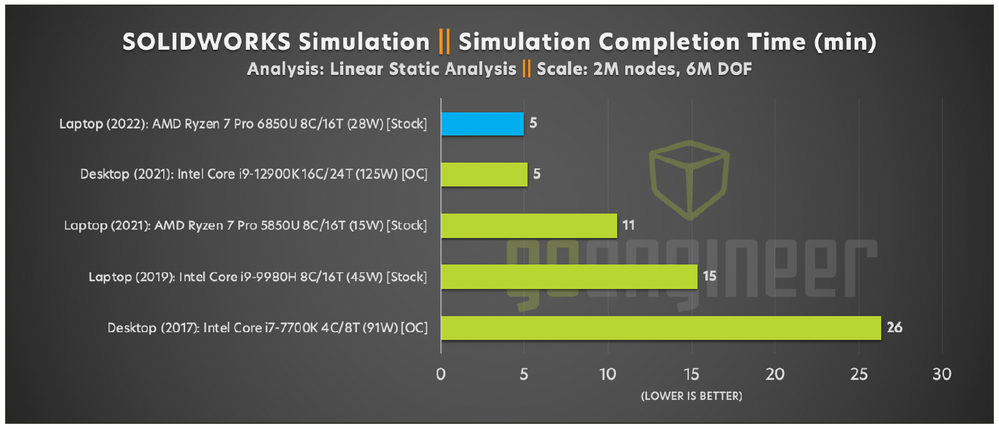

PERFORMANCE: SOLIDWORKS SIMULATION

Figure 9. SOLIDWORKS Simulation benchmark results.

SOLIDWORKS Simulation is where this machine ran away from its predecessor with a 55% improvement to FEA solve

speed over the 5850U. The Ryzen 7 PRO 6850U’s almost doubled power budget over its predecessor (15W to 28W)

clearly pays off over sustained loads, in what appears to be a proportional manner.

Figure 10. SOLIDWORKS Plastics benchmark results.

In SOLIDWORKS Plastics, the P16s was once again a clear win for the new laptop and its 6850U, likely thanks to the

increased power again.

PERFORMANCE: POWER CONSUMPTION

As a low-power processor, the Ryzen 7 PRO 6850U did well to keep the ThinkPad’s 4 Cell Li-Polymer 52.5Wh battery

going under various workloads. After using the P16s as a daily driver for a few days, we observed the following battery

life results:

Charge Time: 80% after 1 hour

Office Work (including web meetings): 6-8 hours

SOLIDWORKS: 2-3 hours

When it comes to temperature, the P16s does a better job than the previous generation P14s we tested at dissipating the heat that builds up under sustained load, especially when the GPU is cranking. However, we still recommend propping up the back end to help with air circulation under the machine.

CONCLUSIONS

From our testing, the Lenovo ThinkPad P16s (and by extension the P14s Gen 3) is a marked improvement over the already competitive P14s Gen 2. It provides a comfortable entry-level SOLIDWORKS experience in an ultralight laptop

form factor, with impressive simulation capability as well. It’s hard not to look at these as an option for designing assemblies under 2000 components.

The Lenovo ThinkPad P16s and ThinkPad P14s Gen 3 are great choices for moderate CAD users who design assemblies under 2000 components and run the occasional finite element analysis. With a great price point under $2,000, you will have a lightweight, SOLIDWORKS-certified mobile workstation that will serve your CAD and light FEA needs. The generational performance increases on display show that AMD is dedicating serious resources to developing hardware for the commercial engineering market, and working closely with SOLIDWORKS to do it. New competitive pressure in the marketplace is always a welcome sight, as customers benefit from the innovative products that arise, like a powerful ultrathin SOLIDWORKS laptop.

GoEngineer Technical Marketing Team

Bob McGaughey, CSWE

Senior Applications Engineer, Strategic Solutions

Zack Yates

Product Marketing Manager, Software Solutions