- AMD Community

- Groups

- Red Team Modders

- Discussions

- 3D printing stuff

Discussions

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

3D printing stuff

What Printers would you recommend and what programs do you use. I've had this goal of making simple 3d printable Open concept cases. I think it would be cool to go to download a case design and be able to print it all at home. Every printable case could list compatible parts. Most mounts are universal (PSU, motherboards, etc.) but will be some variety in cooling Solutions. So far I don't think anyone has done this yet. I had the idea when I purchased a MORA 420 core. I wanted to figure out a way to strap a motherboard trey to the MORA420 and use the RAD as the stand/case. I love open cases and in my experience they run and look cooler. I feel this is something a lot of people would be into. But to start, i could use recommendations on printers and program.

Edit: thingaverse does have a few.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Solidworks gets tossed around a lot as software. Construction sites tend to use it for 3D blueprints. it's not cheap. they want a subscription. You might check out the open oceans but you will never be able to publish under a YARRRR edition. Blender is free 3d modeling I think it can 3d cad,, but........ um.... I am a tightwad and I'd rather pay the subscription then try to get that to work consistently. Believe it or not UT engine(video games/movies engine gets nods in design spaces to I don't think it cads. I know my favorite 3d printer channel is INTEGZA. He is a Portuguese, Tomato shaming, Genius! He made a 3d printed( and pressed) turbo jet ( like small 747) work for about 4 seconds. I believe some brands like Creality also have their own software/forums/CAD. I do not have a 3d printer. but I have dabbled in the 3d model space. Solidworks is where I would start if I wanted to start modeling for a print I would also be interested in can you switch tooling for Machine CNC/Laser. Since the base code is similar, I have tweaked cnc code(very little but I get ZYX in milliseconds/travel.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

thanks man! that is good info. Ill look into the printers. I would want to go free for software if possible. God i would love more time, and access to a CNC and/or 3d printer. Life is too busy. lol only 20 more years to retirement.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

at least in CNC best advise is run slow if you want it pretty, Also alot easier on your bits. get rid of debri fast either vacuum, wet, or pressure. Milling bit for coarse, then use a finish bit/ polish. leave some material for the fine. slow is more time but easier on the bits. Heat in the bits is bad so go slow. When I edited cnc code the 3d proprietary software would spit out a glorified HTML file. we then changed the file extension and changed values in what was a X Y Z axis, positive or negative value. Their was a base multiplier towards the beginning we knew to slow down or leave be based on the Model engineer. Some model engineers we knew to look for collisions or tool changes. Running the code through a digital emulator to catch collisions before it chews holes in funny places is a good idea.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

I will watch this discussion topic, as I have been curious about 3D printers for a few years but I never invested in one. I understand that you need good ventilation when they are printing because you are melting plastic. However a case is printed, can I assume you would make it in several parts, like a HDD cage, a motherboard tray, and the empty case? You would want to make it adaptable to several component loads, right?

As Albert Einstein said, "I could have done so much more with a Big Al's Computer!".

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

yeah, I have worked with the MORA before and it has a place for 8 (m4?) screws. To start, I wanted (my goal) to make the most basic apparatus i could to mount the RAD to a simple mother board trey (i have standoffs) and find a way to mount a PSU, a D5 pump, small res, and optional fan (for VRM/ram) I think it would be a cool project. The possibilities are limitless. I would assume with the more readily available 3D printers, Case printing and MODs are going to become quite popular.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

resign printing is a totally different ball of wax. Stuff extruders cant do become makeable. In extrusion printing yes smaller parts fasten together. If I was going to "print" a case I'd go small first like micro itx. I worked in injection molding too for electronic connectors /switches. Pro's use pins and helix fittings from motorcycles. Hotwheel uses a Mattel patented thick guitar string as a pin axel. You can buy 3' of it for like $2 and it is perfect pin materials for supports and pivots(contra Fan's are cool) save a small hole for helix and pins heat ends with a lighter and weld in. Much of picking a printer is how big can it print,, bigger is more money. what software does it use and how good is it? what materials can it print? How modifiable is it If I wants something different? Ender get's mentioned alot there seem to be 2 good printers ender five super special whatever edition and ender 1? super something else. I would want changeable heads for different materials.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

This is pretty cool

https://www.thingiverse.com/thing:4304174

or

https://www.thingiverse.com/thing:4567519

ohhh i like this

https://www.thingiverse.com/thing:5221552

yep. Gunna get a printer....

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

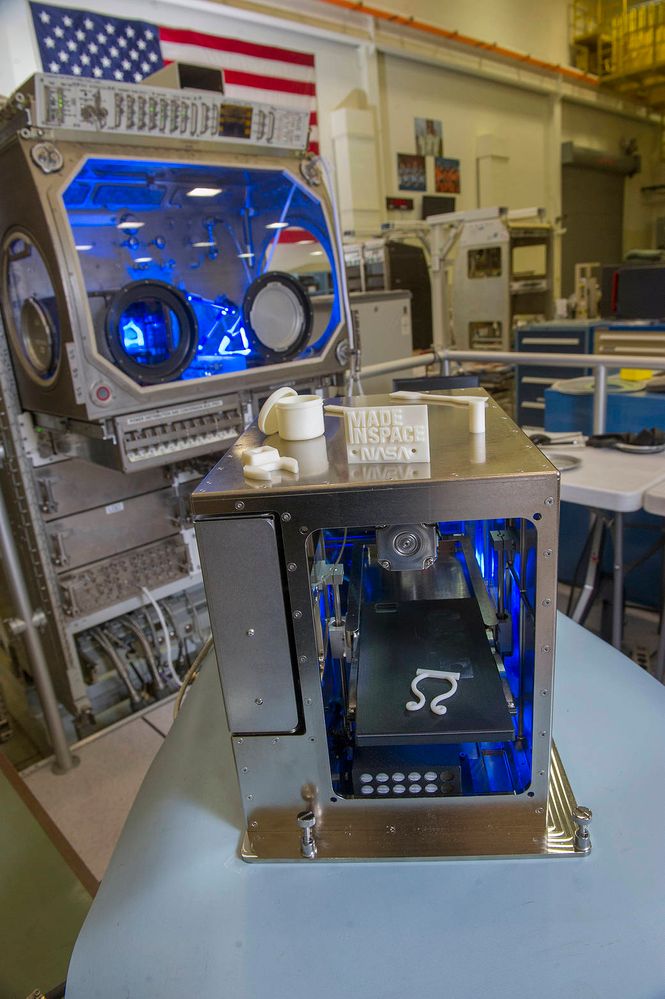

I like the middle one (red frame) because it has a normal size PSU. If you become an expert in 3D printing, maybe you can get a job on the ISS. They have a printer up there, printing custom replacement parts.

As Albert Einstein said, "I could have done so much more with a Big Al's Computer!".

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

I have limited skills and experience, but this is what I have learned from 3D printing:

- For designing things, you can use Fusion 360 which is free for non-commercial use. While it has been upgraded many times over time and GUI has changed, I found these youtube videos helpfull in learning how to design things: https://www.youtube.com/user/cadcamstuff

- The hard part of 3D printing is not design, it's printing and all the details that affect end result.

- For slicing I have used Ultimaker Cura which keeps changing a lot as it is upgraded. The thing I didn't know in the begining is that you actually need many of the options to... at some point... create succesfull prints. I my case you had to increase wall, top and bottom thickness to create stronger components. (many assume infill density is important, but no... it offers rigidity, but if you create a component that needs mechanical strengh, surface layers are important. Also something like printing speed is important. If you print faster, layer adhesion is worse and object is not as strong and layers might crack apart under stress.

- So many things depend on so many details, it is impossible to give simple advice. For instance I have to print first layers very slowly and lay a lot of brimm around object so it sticks on a glass surface of my printer. The use tape (while printer is running) to make sure objects dont' warp and detach from printing surface.

- Every print has to be placed on specific location, or there might be issues. This is something I think is not an issue if you have something like Prusa or better. My printing bed glass and heated aluminum bed get warped when you heat them to printing temp.

- Pretty much everything under Prusa prising requires a lot of tinkering

- No reason to get a printer that can print large objects as even small ones take a lot of time and the larger the volume, the more likely it will fail unless it is super simple and printed in vase mode

- I this part I wanted to tell about things you might want to think about when choosing a printer. There are just too many. If you want it to go fairly smoothtly, get Prusa or something even more expensive. If you are willing to tinker, try, fail and try again time after time just for the fun of it, get something cheaper. My poison is Creality CR-10 mini and despite upgrading it, I have to adjust the thing for every single print by trial and error. If I knew what I know now, I would get Prusa or something else that doesn't require so much time and effort.

- 3D design is a great skill and you can find many practical uses for it - if not for anything else, than just for 2D prints of your rendered creations, but printing 3D is... still something that.. If you get Prusa or better, is fairly doable. Anything below that and you find yourself battleing with details to get decent prints out.

If you want my advice... get Prusa or better.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Great idea! For printers, the Creality Ender 3 or Prusa i3 MK3S+ are solid choices. For design, try Fusion 360 or Tinkercad, and Cura for slicing. Starting with universal mounts is smart, and using the MORA 420 as a base is a cool concept. You can Download Now to get started with the necessary software!