Graphics Cards

- AMD Community

- Support Forums

- Graphics Cards

- 5700XT hot die.

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

5700XT hot die.

I own a Gigabyte Gaming OC RX 5700XT, and over the past year the junction temperature (which I believe is the die) has been steadily increasing with okay edge temps.

About a week ago it got to the point where the card was thermal throttling with the fans at 100%, even when running at 1900 MHz and 1160 mV. There is some sort of issue with how the die is interacting with the cooler, not sure what.

On the first day of my attempts to fix this thing I opened it up and sure enough the thermal paste was flaky and sparse. I cleaned it off with some isopropyl alcohol and replaced it with Arctic MX-5, along with the thermal pads since they were torn. I am reasonably confident the thermal pads are the right thickness since I asked Gigabyte support for the thickness and they matched up when I compared the new and old ones.

For some reason, this made my temperatures worse. Now it immediately shot up to max temperature under load and makes games even more noticeably unplayable. Apex Legends is full of stuttering from the card downclocking from heat.

As far as I know no one else has had this problem that I could find on the internet with ONE exception being this guy on reddit, who seems to have the exact same problem with the exact same card:

View: https://www.reddit.com/r/AMDHelp/comments/ghwo6j/gigabyte_gaming_oc_8g_high_junction_temps_after/

I posted my own reddit thread and one nice person helped me but I still haven't solved the issue. There are some pictures there as well:

View: https://www.reddit.com/r/AMDHelp/comments/pbtnp4/very_high_5700xt_junction_temperatures/

Since then I have been trying all sorts of solutions for the problem and the results have ranged from being terrible to not being able to POST my computer.

- Using a washer mod (most of the following I tried with/without):

- Running the card without the backplate (spacer pads are on it so they might effect pressure)

- Running the card with the backplate with an additional spacer bad behind the die (this made the backplate very hot)

- Upping the thermal pad thickness (I essentially added 0.5mm thicker pads)

- Running the card with the backplate for rigidity, but with all the spacer pads removed

- DDUing the drivers and reinstalling them

- Pressing the layers together with hand while under load (bit hard to do with the fan design)

- Checking the cold plate and heatsink for flex (none that I could notice)

- Very little thermal paste, and excessive thermal paste

- Putting a piece of paper in between the die and cooler, then tightening it down to check the tightness (without washers it easily came out, with it was firmly in space)

- Barely tightening the screws past when they bit. Tightening the screws as nonexcessively as I could.

- Trying different PCI slots when it wouldn't POST

- Comparing temps of the backplate and air from the fans. Under load the air from the fans is cool and the backplate is very warm.

- Watching temps: When the computer starts up it is actually quite good and around 50 degrees celsius but after being put under load it stays at around 60 and the fans have to constantly run at about 40 percent to keep it there.

I have no idea why the cooler does not want to cool the die. With or without washers after I take the cooler back off, the thermal paste seems fine and evenly spread. I am at a total loss. Someone please help me so I don't have to spend 5 million dollars on a new GPU!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

You have happened to come across one of my 4 favorite topics in which to rant.

You got me in a good mood, so here goes.

There are 3 ways to transfer heat.

Conduction. - A solid object absorbing the head from another solid object (This is the best way to transfer heat)

Convection - Vapor or a liquid carries away the heat. (Second to Conduction, )

Radiation - The heat radiates across a void. (for example the Sun, or Toaster coils) The least efficient way to transfer heat

Radiation is so bad, it is almost like insulation. When it comes to conduction, copper is one of the best.

Copper's ability to transfer heat is about 400W/mK, while Aluminum is only about 200W/mk

Thermal Pastes or Thermal pads can be in the range of 5 to 9W/mK

As you can see, Thermal pastes, and Thermal Pads don't do any where near as good as direct Metal to Metal contact.

However, the slow transfer of heat through TIM, or Pads is still far better than an insulating void that traps heat.

Application of Heatsinks to Chips is almost a lost art. People underestimate the amount of effort that should go into the application of said items. A jewelers precision is required.

The aim is metal to metal contact. Period. You get that and you win. Big time.

But it is Not as easy as it looks. People get two shiny pieces of metal and lie one on top of the other and say, oh that's good contact. How often they are fooled. You're telling me that you could pull a piece of paper out between Heatsink and the chip? That tells me you have a deadly, heat trapping void!

Internet users and even Manufacturers (who supply pre-applied paste) take the lazy way out. Manufacturers, when they sell you a heat sink, they supply Way too much Paste on it. Why? Because for them it is better to ensure that SOME contact is made rather than the best contact. Manufacturers can not take the chance that no contact is made.

The more paste that is applied, the greater the distance heat has to trudge thorough that 5W/mK paste. There is a YouTube video where this guy Linus has his two friends Steve and Jay try to find build errors in Like constructed PC's. Paste was missing in both PC's. Steve found the error and applied gobs of it. Jay didn't notice, and his build was completely void of paste. Jay though had better temps in the end than Steve. I laugh at this because Steve made a separate video on his channel, concluding that the application of paste barely matters. However on that video, when he used a "light application of paste", it was still way too much.

So: Here is what you need to do:

You must determine where contact is being made. Clean both surfaces. Then apply the smallest amount of paste to one. You don't want to layer it. It should have almost NO thickness. Think of a teenage girl, how much would she put on a pimple. She would not leave a layer of this. Now Apply (screw it down) the Heatsink to the chip(or board). Then remove it. You should see exactly where contact is made. This is where you have to sand (either 400 or 800 grit). Keep doing this until you get contact in the center. I rather sand the heat sink, it is cheaper. However, your results will indicate what you have to do. Do not worry that the surface is getting scratchy. A scratched surface with a minor amount of Tim, does so much better than a warped one with gobs of Tim between.

My dentist, when he worked on my teeth use to use carbon paper to test the contact between upper and lowers.

You have to test the contact. It's work, but experience has shown me that one can't trust one's eyes when it comes to such things. The results will amaze you. Like I said, it's a lost art.

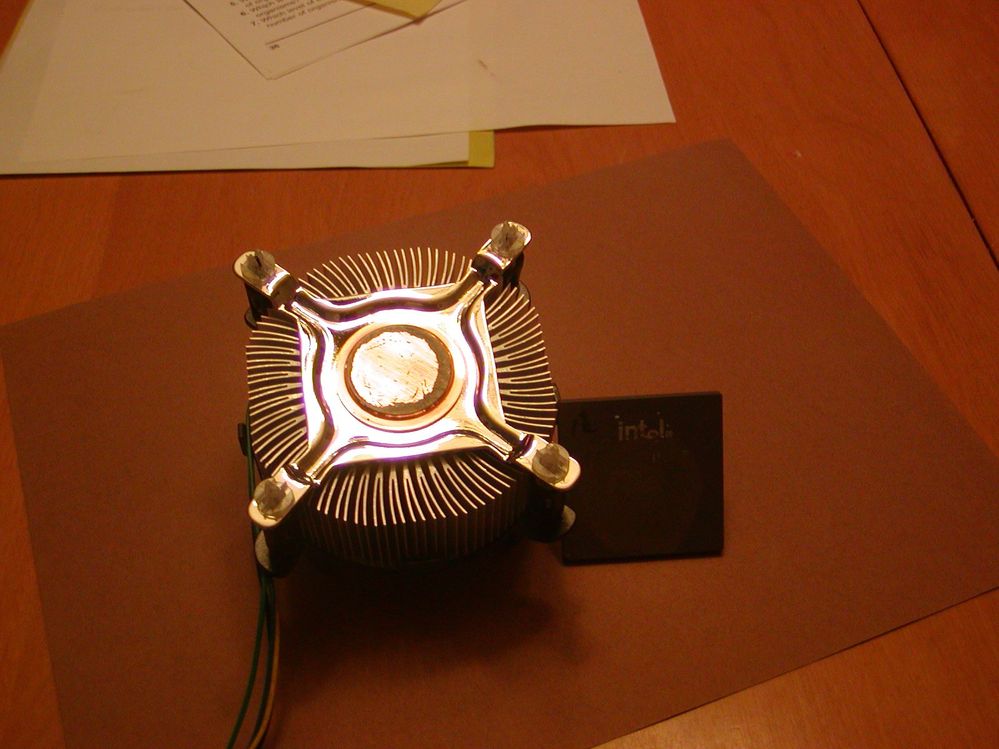

I've enclosed some pictures from years ago, highlighting this topic.

If you do this right, you get a cooler system. You get a quieter system, and you get a faster system.

Good Luck.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hey, thanks for your reply.

The thing is that there does appear to be good contact, but it doesn't behave that way while running. I'm just posting this because I am somewhat reluctant to take sandpaper to my 900 dollar graphics card so I wanted to check with you first.

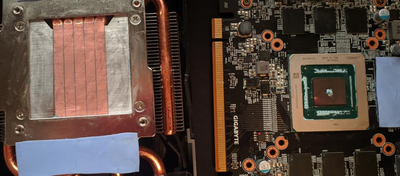

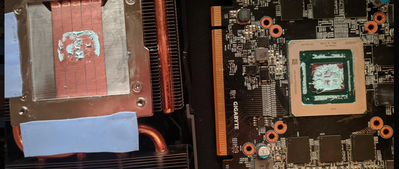

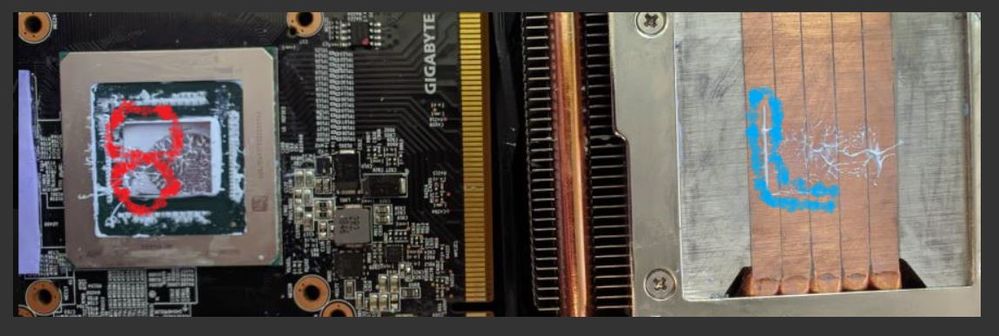

I opened it up after a couple of days after giving up and there seems to be decent contact all over, but I could be wrong. This is with the washer mod:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

I am going to be blunt, so don't be offended.

But there is no such thing as "Appear to be good contact."

One can NOT tell by appearances. One must Test.

A Child can take a dollup of Thermal paste and make imitation Smores.

But the result will be Two pieces of metal that come close, and a thick blanket of Thermal Grease.

You realize they coated the swimmers with grease and butter when they attempt to swim the English Channel.

What I see in the picture, is so much paste that it actually spilled over.

You need to know where they actually touch, or if they touch at all.

Clean up that mess on both surfaces.

Spread the smallest amount of TIM on the GPU. (not much more than a greasy finger print) (in your final application you can use more, we are just trying to determine where and if contact is being made)

Screw the clean heatsink down on the GPU, then unscrew it and lift it up. What does it look like? Did it transfer to the heatsink in the center? Post the pic. (I doubt it, because you said that you could pull a sheet of paper through, and the amount of TIM should be thinner than the paper)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

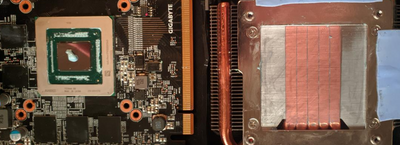

There you go. Did three tests with differing amounts of paste.

Also, I was not able to remove the paper when using the washer mod, which I also did here.

Thanks

Edit: Sorry bout the formatting, not sure what to do about that.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Thanks for the pics.

I'm not sure what you mean by the "washer" mod. Is that some sort of shim you use to take up space?

However back to topic,,, The pics are handy because it shows me you don't understand what I'm trying to say.

We are NOT trying to find out how much TIM you will use on your eventual mounting of the Heatsink.

We are looking for a VERY SMALL amount that will show us where it contacts.

At best use only 1/5 the amount you put on your smallest application. Do not leave it in a Ball or Mound.

Spread it out Completely over the Entire GPU chip. You want it so thin, that you would not consider it as a layer. Because any height used by the paste would represent a gap that was acceptable to you. And trust me, you don't want any gap.

Think of it as a Teen age girl. Would she go to the prom with THAT on her Zit?

No! She would spread it out until it was Almost Invisible!

You just want enough to leave a finger print. A gap that can let a piece of paper slide through is Way too Large and it would cause A very Hot Chip. You have to be more precise!

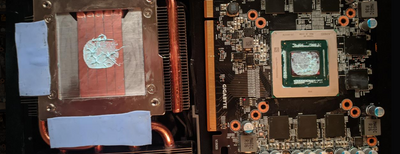

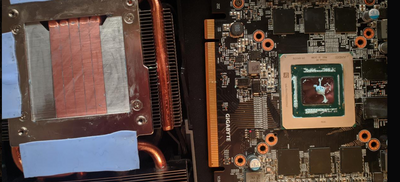

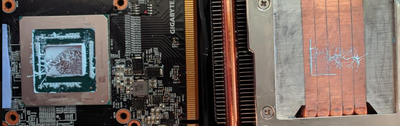

If you go back to my pictures, you will see an old Gray Pentium chip covered with the smallest amount of Artic Silver. The Heatsink was pressed up and then removed from the Pentium. You can see where contact was first made. The Intel heatsink had a "beer ring" impression. If I used any more than a slight smear, the whole processor would have been covered and I would not discovered the high spots. Note the same thing happened on the base of the Artic Freezer. Three sides made contact and got covered with paste, but the 4th side and the center made no contact. Also note, that the Processor and both heat sinks looked perfectly flat and shiny smooth to the eye. When laid down on the Pentium, You would not see any light shining though. Why? Because the edge was the highest spot and that would have blocked out the light.

Test again, and repost results. Again think precision.

You might want to search on Amazon for "Copper Shims" You want to find the thin ones, and various sizes.

I say this because from your posts it seems like you have way too much space between the cooler and Heatsink. If you go with the shims, tighten the screws till you feel a good tight, but not overtight.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

A washer mod is just placing nylon washers on the spring loaded screws so they create more tension and pressure on the die.

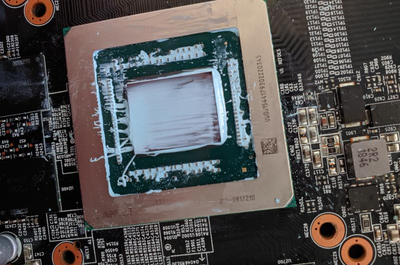

Here you are. I tried to spread it as thin as I could with an old card.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Thinking of the Noctua attachment mechanism...

Maybe I don't have the correct visualization on this, but...

If you put washers on the spring loaded screws, they would bottom out earlier, thus not allowing you to screw down as far... this would result is less tension on the Processor...not more.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Could have been a little less... but now we are getting somewhere..

You can see by the Blue circles where the ridge is making contact first. These Blue area stop any red areas from getting contact..

There is a void in the red areas, and they can only rid themselves of the heat, by having it to transfer to another part of the heatsink.

Now let me say first, that this might not be the worst contact I've seen. I don't think it should have made the thermals as bad as they are, but they did contribute to them.

Before sanding the heatsink in the area of the blue (with 800 grit or finer). I'd clean the heatsink once again. Take another impression, and verify that your contact pattern is somewhat consistent. (That is, that it is not because of screws tightening.)

If you get a consistent pattern, I would sand down the area of high contact (The blue parts). I personally don't worry that the heatsink gets scratched. You would be looking for a more overall contact pattern for your final result.

But what you do is up to you.