Gaming Discussions

- AMD Community

- Communities

- Red Team

- Gaming Discussions

- Re: A post-mortem of a Corsair H100i GTX AIO after...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

A post-mortem of a Corsair H100i GTX AIO after three years of 24/7

As a few of you know I did some upgrades this year that went pretty well, except for one major mistake on my part, and that was when I connected two Enermax D.F. Storm fans to my Corsair H100i GTX AIO cooler (120x240mm radiator), and the current draw fried the fan controller in the pump/block forcing me to have a H100i V2 overnighted from Newegg to replace it, and the purchase of the Aquacomputer Aquaero XT 6 to control both the D.F. Storm radiator fans (on the new AIO) and the D.F. Storm case fans. For those unfamiliar with my main rig, I have a description of it here: https://community.amd.com/thread/230494

Since doing this, I decided to do a post-mortem on the H100i GTX to see what exactly three years of 24/7 power-on time does to one, and that is what this post is about.

Caveat: This rad was functioning acceptably prior to my stupid move with the fans. Despite what you see, keep this in mind. What I am attempting to do here is to educate and inform. The warranty on this unit was five years. Most people don't run these 24/7 like I do, so the usage pattern here could actually be closer to the five year mark for most people. I don't really like my HDDs going through a lot of power cycles, so I run for continuous uptime, and that's how I ran with WD Greens without issue for over five years, and after upgrading to enterprise WD Gold drives, the same policy is in place.

My advice is that although these may still perform acceptably after the warranty expires, do not rely on it to continue to after that period. Continuous uptime use for three years to the month produced what you are about to see in mine.

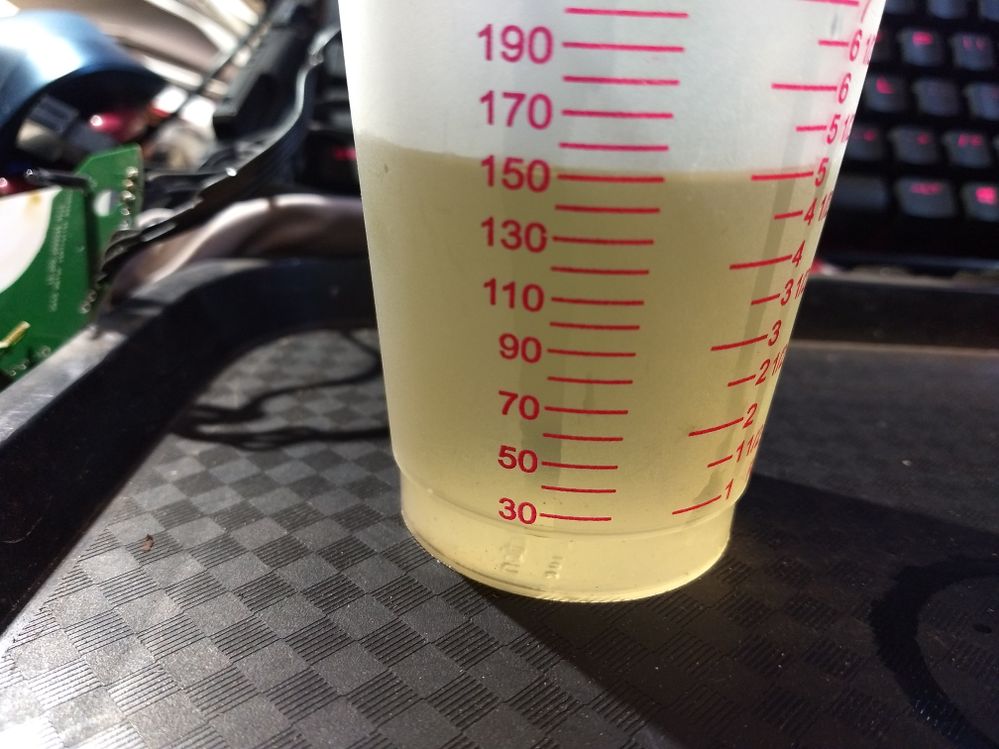

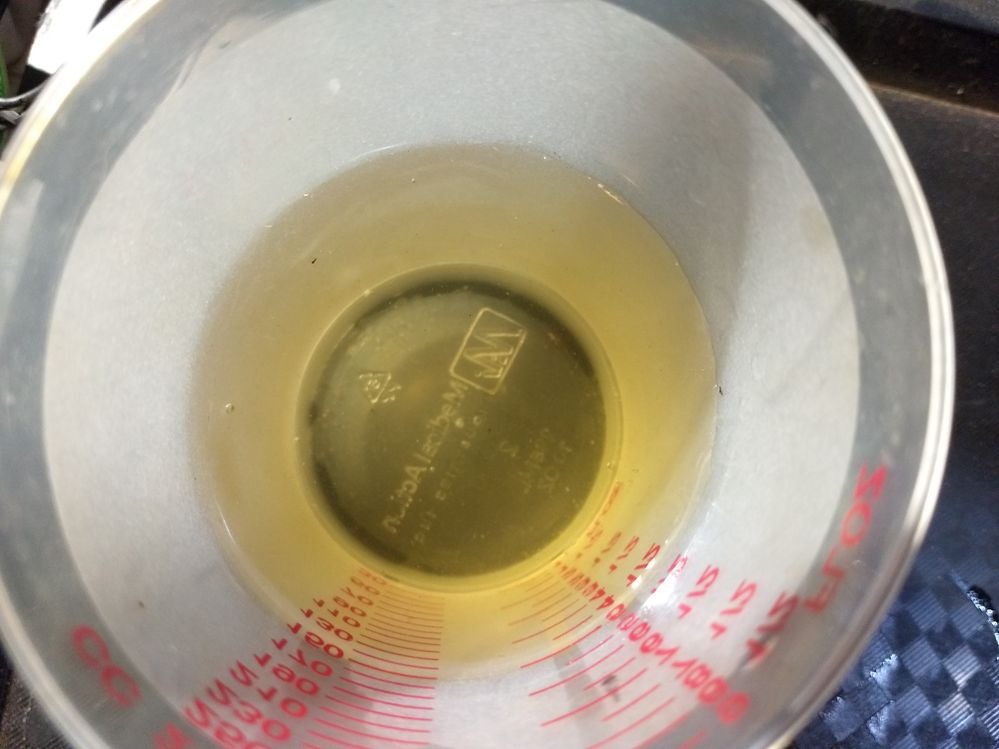

As some of you might recall, one of the improvements that they touted with the GTX version of the H100i was the lower evaporation rate from the new tubing. Based on other sources, and from a GN teardown of a new Asetek rad of the same size, I found that their claim here seems to be true. I estimate that in addition to what is measured in the cup, there was another 5-10 ml in the pump and in the rad itself that was a little more difficult to drain, plus maybe 5ml or so of spillage during disassembly. Accounting for estimates of unaccounted for fluid, I'd venture to nail the fill level at 165-175 ml at the time of disassembly.

The liquid did appear to be clear, but there were some dark "bits" in it as well.

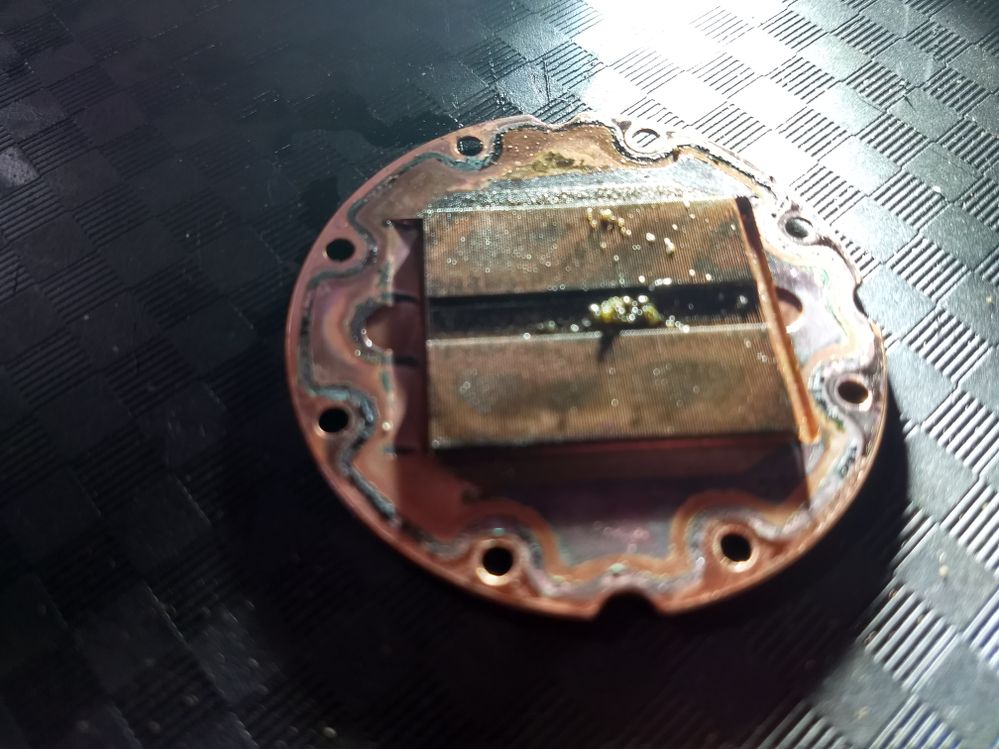

The rubber "jet" fitting that goes over the microfins and functions as a seal was pretty nasty.

That was just a preview of things to come. The first picture here is a little blurry due to focus issues, but it was the first picture of the revealed micro-fins. The second picture is a bit sharper. The third picture is a bit blurrier, but shows what was resting on top of the fins too large to fit into them. You can see clearly that there is a large wad of squishy debris in the middle, signs of corrosion of the copper is visible and possibly electrolytic since the rad is Aluminum. The dark regions in the micro-fins were caked to the top of the fins, and to date has largely even defied a toothbrush (dry) in attempting to get it out, although the bristles have difficulty getting in.

In conclusion, if you run your system hard and constant-on, be vigilant with watching your temperatures, and maybe even obtain a spare in case of failure after the three year uptime mark. After the warranty expires, it might be a good idea to retire the AIO to a less important system even if it is still operating fine. In most cases it will be cheaper to replace the AIO than to replace the CPU.

What you see here is probably the situation in all Asetek manufactured AIOs after similar uptime (Corsair, EVGA, NZXT, Thermaltake, etc.......the list is long). IMHO, they need to put some effort into better post-manufacture cleaning of the radiators before assembly.

Don't let this put you off on using an AIO. This was operating within expectations and experience up to the time of failure. These units enable overclocking and long life of CPUs, and still make for less wear and tear on the PC board of the motherboard than what I call BAHHSs (Big-_ssed-Honking-Heat-Sinks).

This post is provided for information only. Your AIO may have different results.

Message was edited by: Jim Bryant Due to problems uploading the rest of the pictures, this had to be finished in a post-posting edit.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello,

My water-cooling system is made by 2 Corsair AIO H100/H100i fused in a single loop, with a tank as any custom water-cooling.

I found the same type of clogging when i dissembled them the 1st time, but not sure this is due only to the manufacturing process, I thinks it's also a combination of corrosion and precipitation.

I agree with you, i had a hard time cleaning the whole loop/block multiples times if any dust would fall into the liquid when assembling.

But i think the primary cause of degeneration of these AIO is the evaporation of the liquid and concentration of solutes into the cooling liquid.

The evaporation cause a negative pressure that need to be filled by air and slowly could get some dust in the loop, but also the corrosion an precipitation help a lot mixing everything into this green stuff i also found.

Imo the build material of these AIO are good an meant to last, but the coolant will fail soon or later due to the evaporation.

Reusing old AIO in a custom loop is a great idea for a cheap water-cooling as i did, greatly extending it's lifetime and it's performances.

Aside the same clogging you reported, i also noticed that the loop was not filled completely with liquid.

I had a hard time filling the loop compared to a normal custom rads, making me think that these AIO are not completely and decently filled when coming out of the manufacturing process.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

I'm almost certain that evaporation may not have even been an issue. Their new tubing may have done the trick. I also don't see any way that dust could have entered the internal system after manufacture, as the tubing was fitted very nicely, much nicer than I ever thought since the fittings at the rad itself have a flimsy wobbly feel to them, but the barbs are quite long, and the tubing was deep onto the barbs and very firm. I'm guessing that what we are seeing is largely manufacturing gunk and corrosion bits. Fudging up a bit from my unaccounted for liquid and spillage guess, 175ml might be the magic number they used at the factory for filling, and it may all have been still present. In the summers the ambient in the room can get into the mid 90's F with most of the summer 33-34C being a rough average temperature in the room because of our cheesy tiny window air conditioner.

I did save the rad for future use, and it does seem to be very usable still, assuming I can find some tubing that matches the barbs for use in an all-aluminum setup, maybe using some of the EKWB aluminum stuff.

What surprised me the most was that it was still working within expectation and experience up to the point of failure, even with all the gunk.

Oh, and even brand new, it was obvious that there was a lot of air in the system, and you could heat it just mildly shaking the thing. I'm guessing that they don't fully fill them at the factory.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

I used a rad from an old AIO I had, and I just went to Home Depot and got a couple reducers there. Works like a charm. Might as well re-use what you can.

Discord https://discord.gg/pttrmDpeVN

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Thanks for the postmortem, love seeing reliability/component after usage post. I bought H80i V2 and used it for several weeks because I was curious with its thicker 120 mm radiator. Went back to good old HSF though because of heat soak with my new RTX card. The tubes are awfully thick, I would be surprised if there's any evaporation issue. I wonder what those gunk are created from? broken micro parts that got covered with mineral from the liquid?

I'm probably keeping my H80i for a future build, but I wonder though how the liquid quality will fare and how to ideally keep the kit? I live in SE Asia and my room is HOT + humid.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Well, this part of Texas may not get the humidity you get down there, but we probably get all the heat (although we have actual winter too).

I don't think the humidity would be anything more than a fungus issue potentially on the external parts, and I guess as long as you keep it all clean, it's all good.

I would assume that yours works just fine. The only possibility I can think of is maybe some separation in the liquid between the water and the ethylene glycol. I'd give it a good shake to mix it all up again and then let it sit for a while before putting it in something if it's been sitting a long time.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello,

AIO manufacturing is not new, with good consumer result if one check the total n° of users and yet works fairly well against an aircooler.

Meaning that the manufacturing process have developed taking account of issues like leaking or degrading.

I think these may not be filled completely, build with a negative pressure inside the loop.

This will fight the natural liquid expansion due to repeated thermal cycles and lowering down the evaporation.

But i would imagine that this negative pressure would equalize over the time, even if the tubing is thick the fitting/coldplate are the major point of leak.

Then with the liquid slowly evaporating over long time, the loop will keep this negative pressure lowering the chance to leak.

This will lead to lower performances over time, until some failure happen somewhere either leak, clog, circuit board.

Also one need to take into account the corrosion if different kind of metals are used, like often it's the case with copper/aluminium combo.

Galvanic corrosion happen when different metal with different electronegativity are used, creating a charge flow into the liquid.

Also the fact that the AIO is working in a charged environment, could increase a current flow into the liquid increasing the corrosion.

This will cause metal slowly to dissolve into the liquid, the copper green junk we both found when dissembling.

For sure if any other impurity like dust would enter in the liquid, this would maybe increase the chances of building the green junk clog.

Maybe helping the dissolved metal present into the solution to precipitate, forming the junk on the fins.

On top of that, the thermal cycles when heating and cooling also greatly help the corrosion or any reaction happening into the liquid.

Especially in place where the t° is really hot, hopefully engineers take this into account, everyone does not have a 21/23° AC always with him. ![]()

Obviously an AIO cooling a celeron in Finland will be less stressed than the one cooling a 32 cores in India on a long run.

So a lot is happening in a closed loop like these AIO, much more than what would withstand a normal custom loop.

Since i'm running these same old AIO blocks + rads, i'm pretty sure that i will find the same green gunk after 2 year, even running 75% H2O, 25% glycol.

I will take pictures next time i will clean the loop, almost 2 years now since i build this custom AIO loop, still have not failed.

It would be great if AIO manufacturers would also offer loop like the one i did, for the average price of 2 AIO.

2 rads + 1 cpu AIO block + 1 gpu AIO block + small tank => pre-assembled to be filled after been mounted, great performances for a decent price.

Something like this before i stopped to care about, note that now most of the gpu now have a memory/vrm plate, hence a HG10 is not needed anymore.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

As long as it works, it's all good!

IT'S ALIVE!!!!!!! IT'S ALIVE!!!!!!!!!!!!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Ummm, does anyone else see anything wrong with this picture? Maybe I'm just missing something.

Discord https://discord.gg/pttrmDpeVN

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

I've seen worse. I have a friend in Greece whose rig and hardware store watercooling was so Frankenstein it makes this one look like a clean layout.

Clearly Wimpzilla doesn't have any cats. My cats would go nuts with all of that.

Like I said, as long as it works, it's all good!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

It works still enough to get the 6th place on HWBOT firestrike for R9 290 overclocking, note that i have only a bare 2600K@4.7Ghz.

Clearly it not meant to be nice to see, it's more a concept bench table than an actual rig.

Just to show a cheap way to get a decent watercooling, AIO are worth to be reused and work much better than what manufacturer offer at stock.

Tho i think with some time spent doing R&D, one can find a nice way to propose a better looking piece of kit.

Especially if AIO reseller like Corsair would offer an AIO watercooling included and incorporated within their case.

More easily to deal with since no pump needed, one just need to look for a small accessible tank and route the tubing decently inside the case.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Deep Cool has been offering integrated watercooling in some of their cases for a few years now.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello,

It's not what i have in mind or propose.

Deepcool offer an AIO closed loop solution shipped with the case.

Instead i propose a real custom loop based on AIO blocks without a pump, like what i showed you above.

Tho the tubing and tank need to be integrated with the case design itself and routed accordingly to be even RGB shiny if one would.

One would have the cpu/gpu AIO block ready to mount, the whole loop already integrated into the case.

One would have 2 pump, if one fail your rig still will survive, quite a nice feat.

This can't be easily sold as stand alone because it would cost too much to package/advertise compared to the AIO closed loop.

That's why folks like Corsair that already sell case, would implement this idea quite easily.

Obviously it has to be marketed as better than AIO but still with a decent price, otherwise one can directly go toward a real custom loop.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

i get what you are saying. i was just pointing out that they are starting to listen to such suggestions.

i think outside of an aio, about the only things a case company should or could supply practically would be a reservoir, pump, a fill feedthrough, and maybe a drainage feedthrough or ball valve.

i don't think supplying a block of any kind would be practical though, since that is a matter of preference and compatibility with the hardware the customer installs. For instance right now I'm probably going to go with the Enermax TR4 360mm AIO for the 1950X, simply because it's compatible and because it's block is actually made for TR4 chips.

[note to moderator: WTF? Why was this reply rejected by a moderator? PM me please.]

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello,

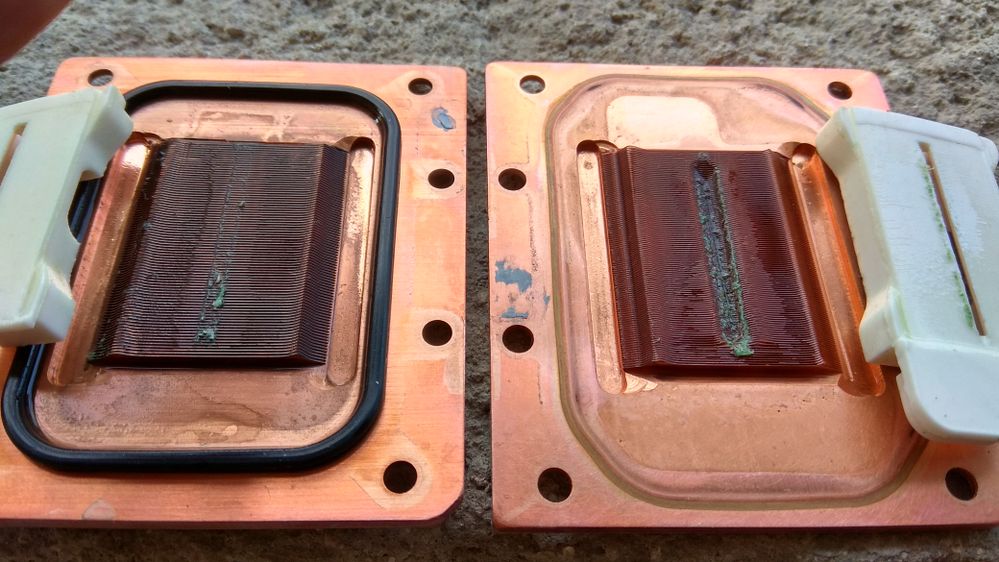

I cleaned the loop and disassembled both the AIO block, here the result after 2 years being in a closed loop with 30%/70% antifreeze/water.

The left block is the oldest H100 mounted on the gpu, it's pretty clean even if i found the same green copper gunk.

The right block is the H100i mounted on top of the cpu, being 1st in the loop it got more of the green gunk acting as a filter.

But on overall both blocks seem to be in a good shape even after 6 years, cleaned and refilled the loop it works just fine.

Conclusion these AIO are pretty good to be reused if put in the right conditions, even the o-ring seems in good shape.

Here the cleaned loop cooling my eGPU setup, waiting i decide what to do since unfortunately my mb P8Z68 Dlx died. ![]()

It seems i killed the Z68 chipset after cleaning and remounting everything on the mb.

Pro-tip: always consider handling old stuff with the care and respect it deserve, not as it is brand new.